— Laser Scanning

Gravida proin loreto of Lorem Ipsum. Proin qual de suis erestopius summ.

Recent Posts

Sorry, no posts matched your criteria.

— Laser Scanning

THE BEST TOOL FOR ACQUIRING GEOMETRIC INFORMATION

We are all aware of the ways in which BIM has contributed to architectural design, from improving cooperation between various specialists, to gathering data in a single dynamic and adjustable model, accessible to all, to reducing costs, in-office working time and risks, and the management of quantities and construction schedules…

What we have not yet mentioned are the various data acquisition tools on hand to make BIM more cost-effective.

Written by:

Catarina Borges Carvalho

Luís Santos, Leica Geosystems

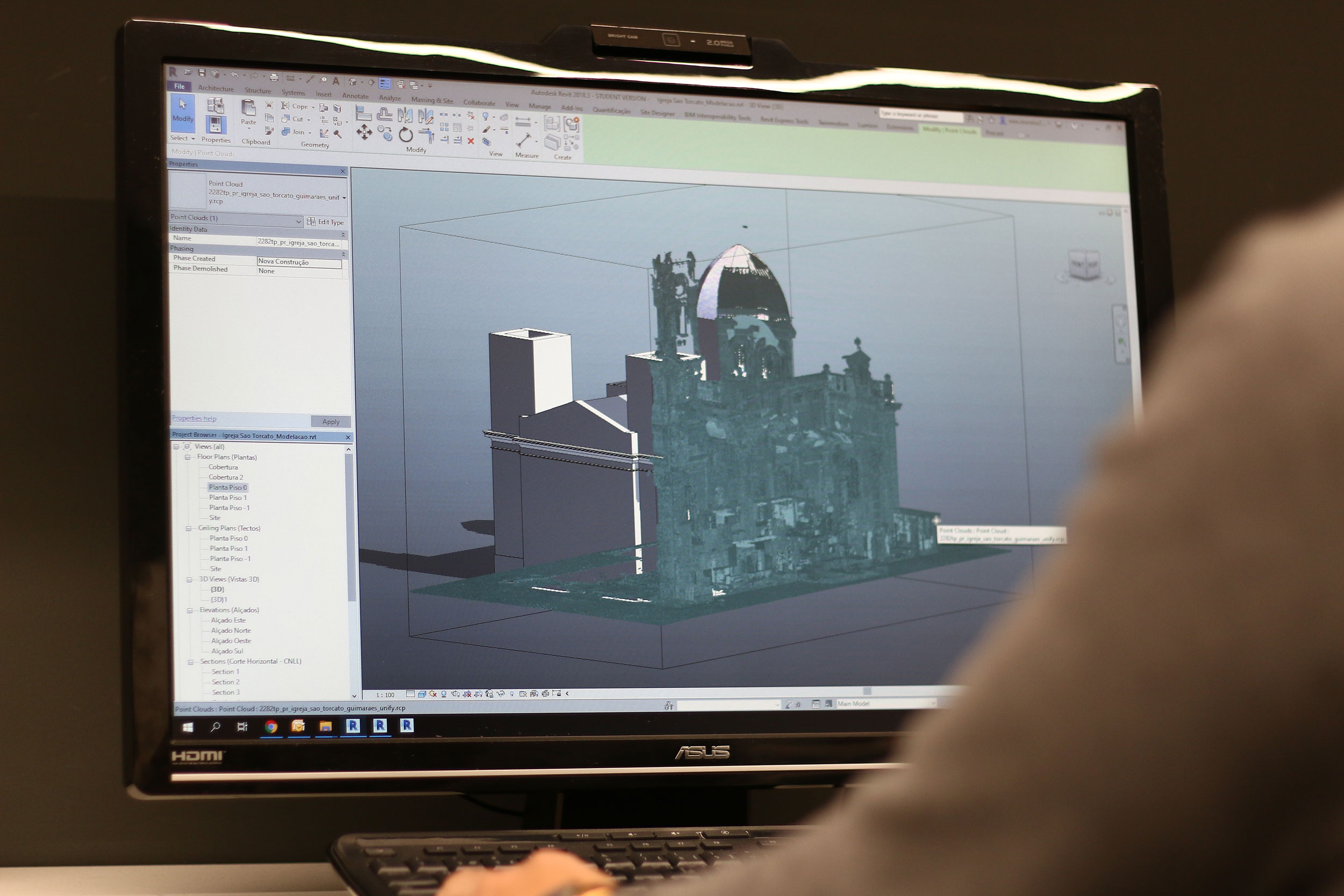

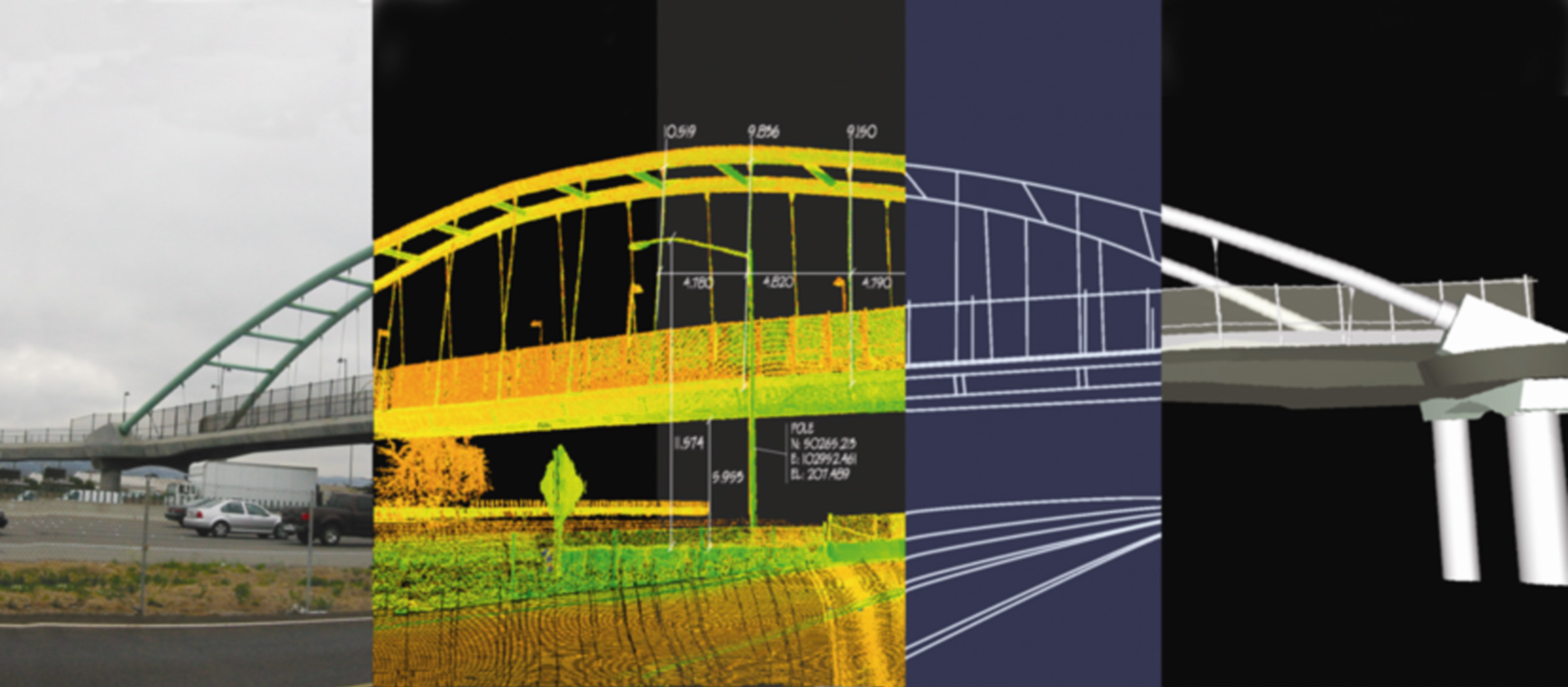

On the assumption that all methods of measuring and gathering geometric information, a rich source of parametric information, are included in the BIM, Laser Scanning proves to be one of the best tools due to its speed, thoroughness and capacity for detail. In other words, it is capable of providing a high level of rich, reliable and precise information in a very short space of time.

However, we must not confuse the two. Laser Scanning is not BIM, but simply a data collection tool which forms part of the BIM process.

“We, the Portuguese, have a very curious way of communicating, which is using acronyms. We use acronyms for everything. And BIM has become one. There are still people who talk about BIM- and use the acronym- without really knowing what it means. Despite what some may think, using a certain software platform to create a model does not make this action in isolation a BIM process. (…) BIM is a whole procedure which makes it possible to recreate a project in the office, with the enormous advantage that all participants in the construction process also create part of the project model. (…) There are various stages to this, not only modelling, budgetary control and decision-making regarding the building elements to be used, but also ensuring that the chosen geometric form is in the correct location, and if it really corresponds to what was planned. (…) As manufacturers of data gathering and management tools and solutions, our main challenge is to ensure that information is made available at different project phases, in any direction (site <-> office), avoiding any losses, maintaining its geometry, quantity and the quality of metadata, which are the most important aspects. Yes, Laser Scanning is a BIM tool, but Laser Scanning is not BIM”, Luís Santos, Leica Geosystems.

I would say that anyone with two or three projects is able to use Laser Scanning. Although each work is a challenge with its own difficulties, it is a technology that is already democratized in order to be used by anyone with field work experience. It does not require expertise.

Luís Santos, Leica Geosystems

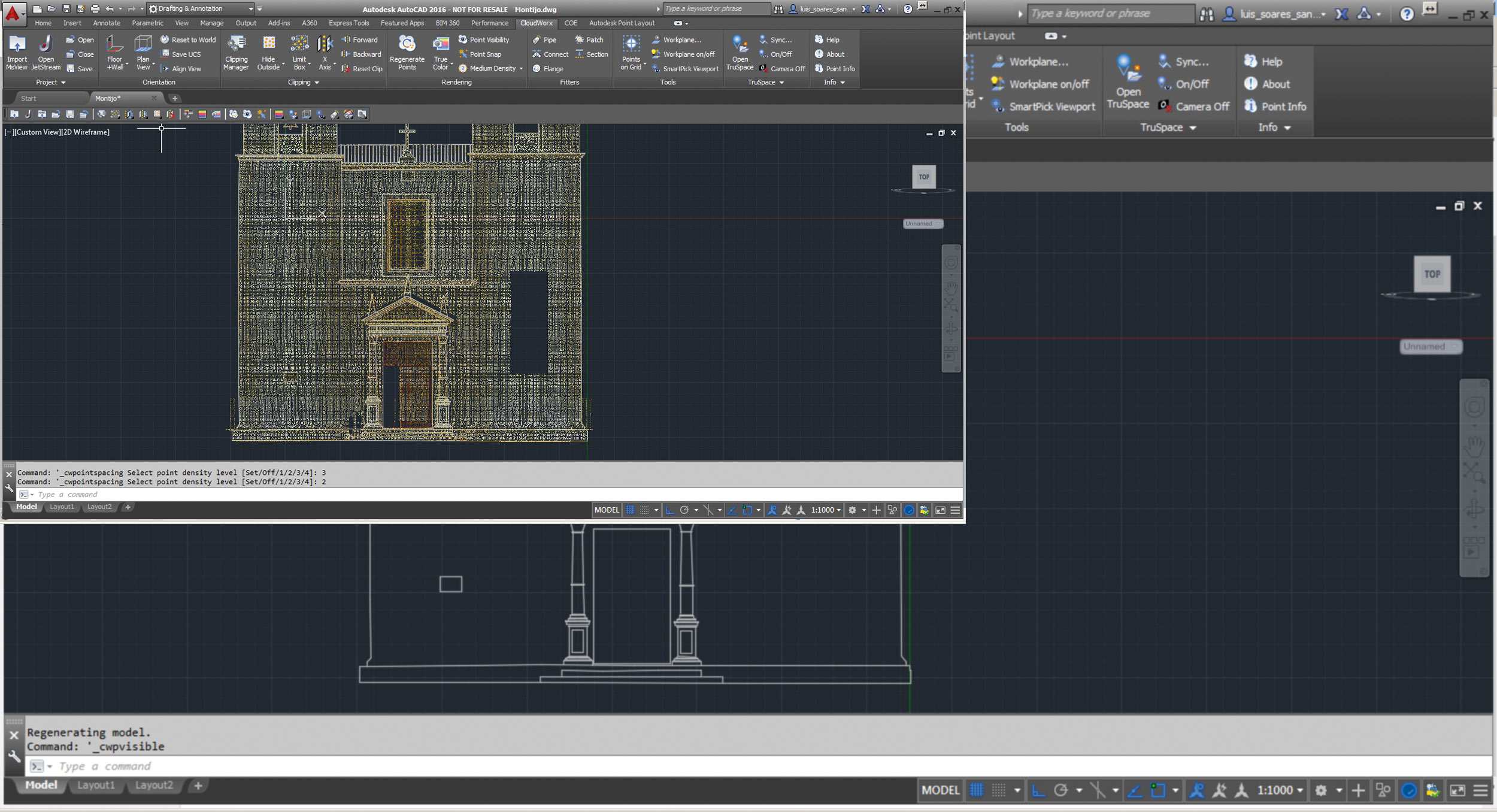

BIM work involves various specialisms, all of which intervene in different stages of the project. Laser Scanning can be used at the preliminary phase, during the gathering of the information needed to build the model; in the subsequent phase, to create final as-built plans; or in the various interim construction phases, to produce as-built documentation for a given moment. Records of the construction in progress are only made possible by regular scans, which provide the detailed information required to understand possible changes to the design throughout its construction, and to validate it by overlaying the point cloud onto the original model in order to identify any areas of incongruity.

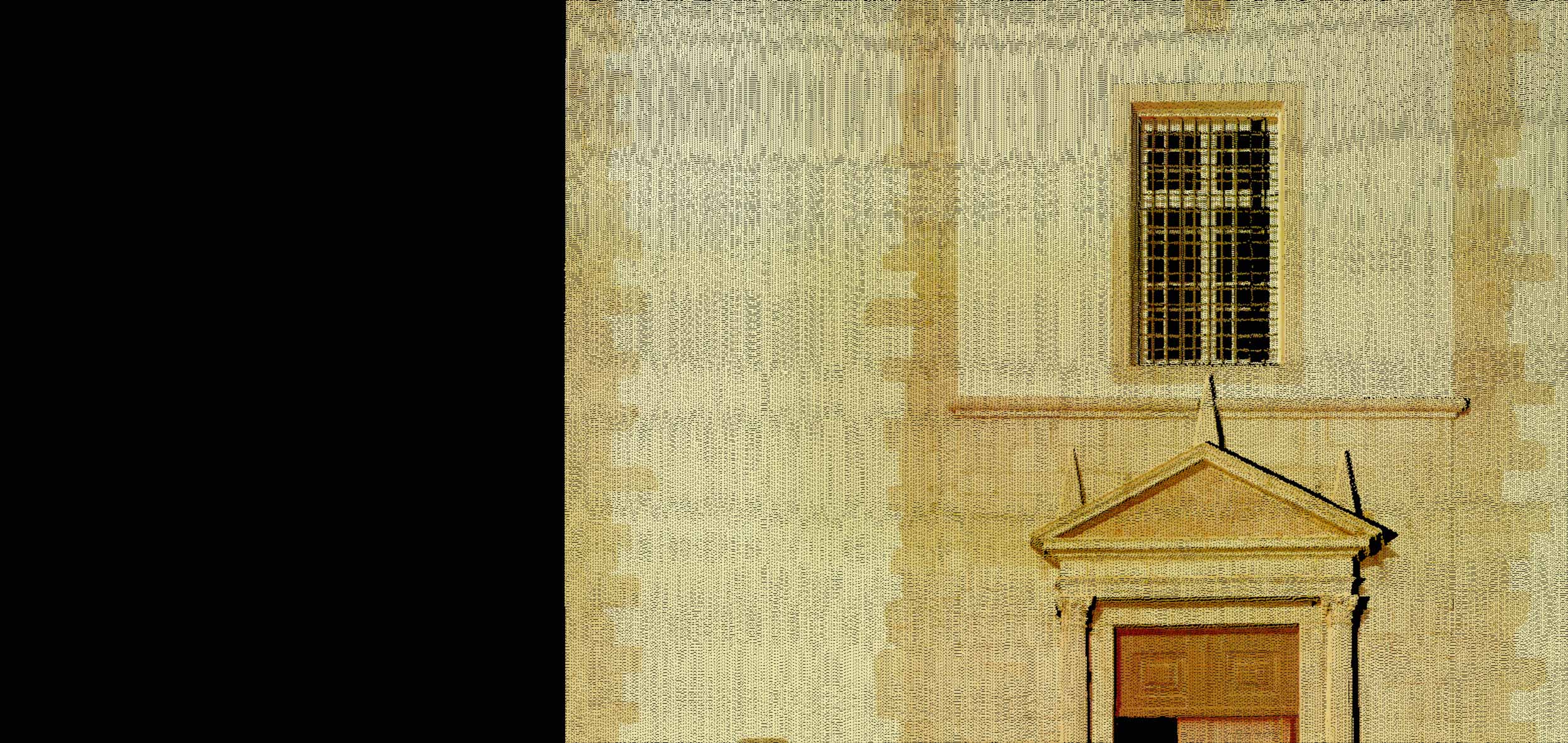

The preliminary information gathering phase has great benefits, for example in renovation jobs. Just imagine being faced with an existing building in need of restoration. Laser Scanning is particularly important here, as, in a very short space of time, (approximately 2 minutes, depending on factors such as resolution and distance), it can provide information so detailed that it would take days to gather using traditional measuring techniques.

Point cloud registration can be carried out using various techniques, which are chosen according to the type of information available. Among these, we wish to emphasize automatic registration of physical points, superimposing areas (“cloud to cloud”), manual identification of shared points or, more efficiently, automatic registration of clouds using advanced algorithms to recognize shared patterns. This has the great advantage of saving several hours of work. All of these techniques can be used on a single project in order to maximize the results according to the information available for each station.

Once registration is completed, work begins on cleansing the cloud. The criteria for this cleanse depends on the objectives of the job, the priority being to eliminate all information which will not be needed during subsequent stages. For ease of data handling and processing, it is also advisable to divide the final point cloud according to the type of work and the object in question.

The better the planning, and the more effective the surveys, the easier, more thorough and less time-consuming the remaining tasks (importing, registration and cleansing) will be.

Given the way in which equipment has evolved, we can affirm that Laser Scanning is now within the reach of any experienced fieldwork technician in this area.